Softblasting

Softblasting with MIRCROPEEN® – abrasive-free cleaning of surfaces

With the iepco soft blasting technology, soiling can be removed in a targeted manner within a few minutes, deep into the pores, dry, abrasive-free and without the use of chemicals.

Thanks to a special blasting agent mixture, the surface of the base material is not changed or damaged during soft blasting. The original surface topography is retained, even with structured surfaces.

Applications:

- Removal of deposits in mold cavities

- Cleaning of dirty extruder and injection molding screws

- Cleaning of overmolded hot runners

Advantages:

- Abrasive-free cleaning

- No thermal damaging of the components

- No solvents needed

- Reproducible cleanliness

- Environmentally friendly

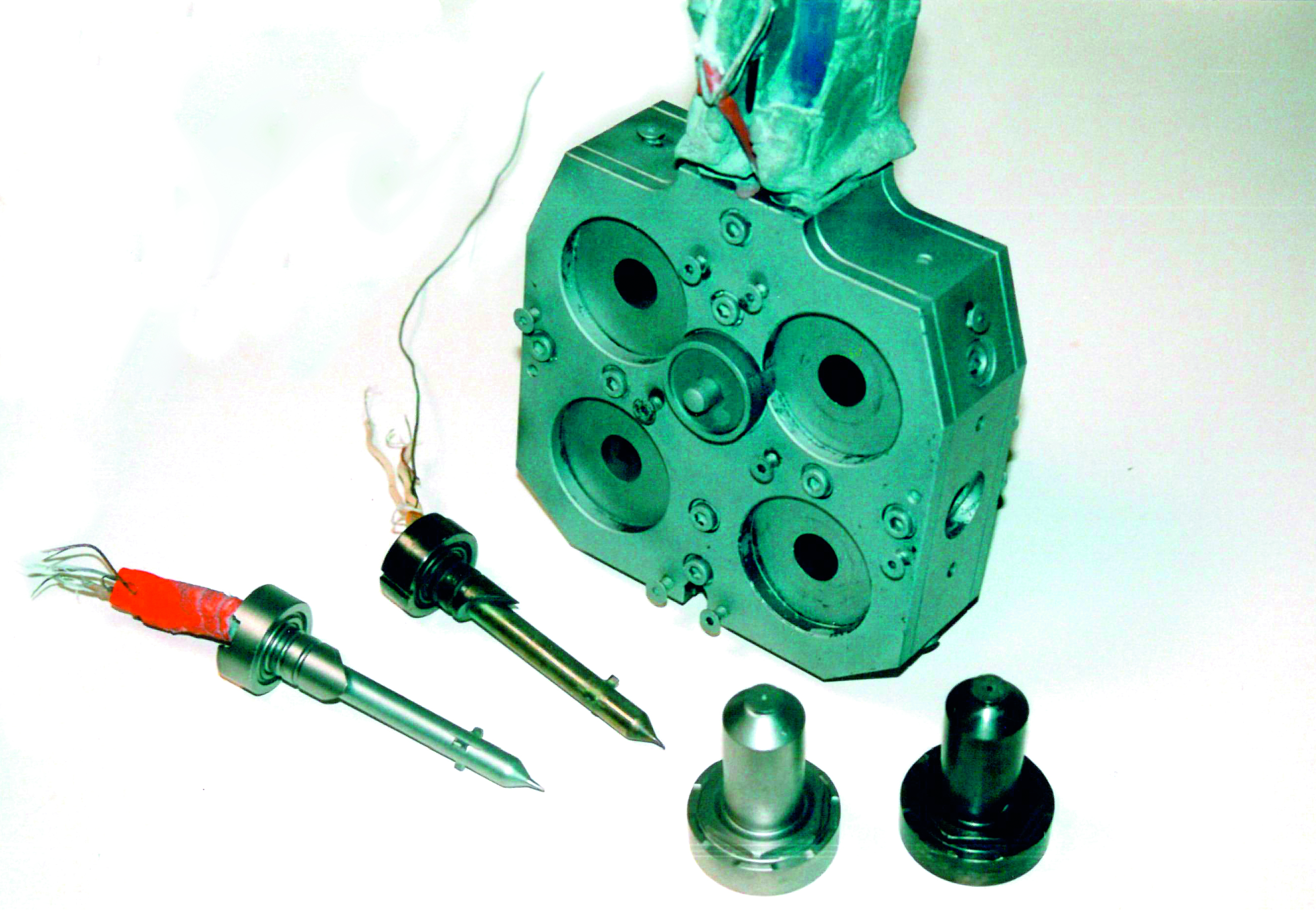

BEFORE

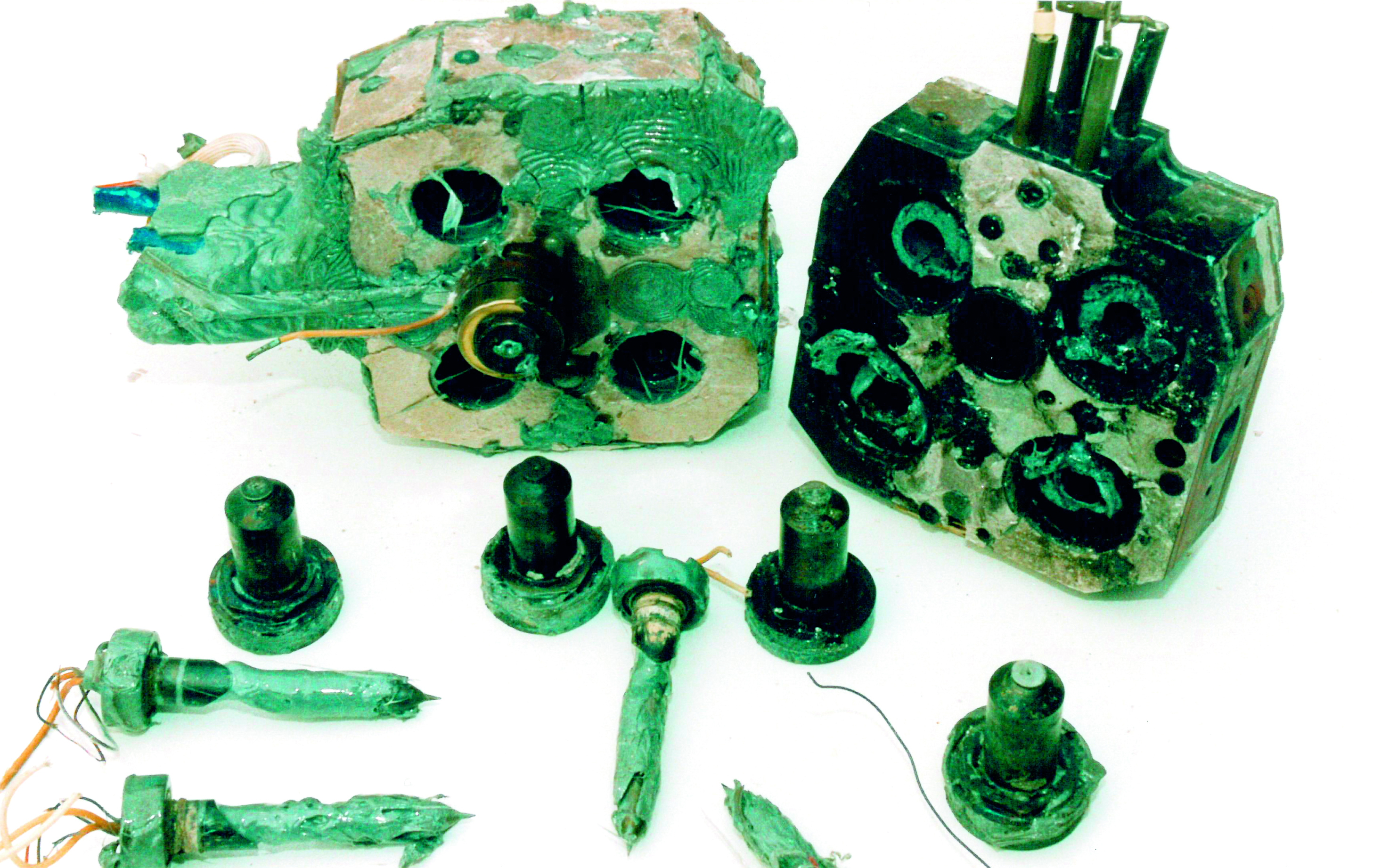

AFTER